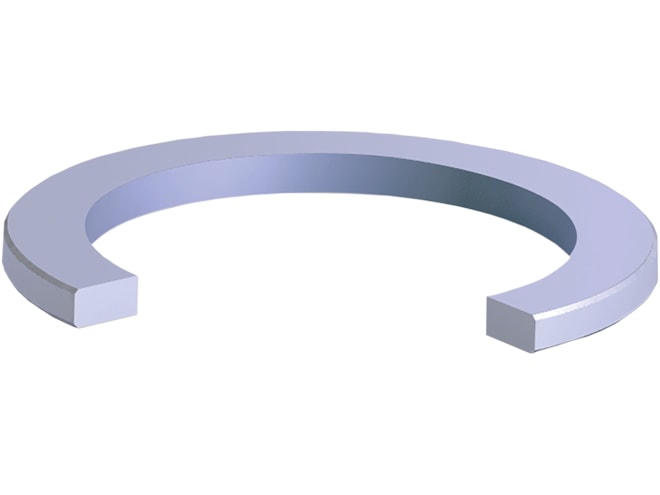

Chesterton 9K Anti-Extrusion Ring

Prevents extrusion into equipment clearances for heady duty, high pressure applications.

Overview

Features

- AWC650 (Acetal)

- -20 to 200°F (-30 to 90°C) operating temperature

- AWC665 (Nylon with MoS)

- -40 to 212°F (-40 to 105°C) operating temperature

- AWC800 (EU)

- -60 to 185°F (-50 to 85°C) operating temperature

- AWC860 (EU)

- -60 to 250°F (-50 to 120°C) operating temperature

- AWC300 (Glass-Filled PTFE)

- -60 to 350°F (-35 to 175°C) operating temperature

- AWC400 (Carbon-Filled PTFE)

- -30 to 350°F (-35 to 175°C) operating temperature

- AWC500 (Bronze-Filled PTFE)

- -30 to 350°F (-35 to 175°C) operating temperature

- AWC520 (Virgin PTFE)

- -30 to 350°F (-35 to 175°C) operating temperature

- AWC630 (Unfilled PEEK)

- -50 to 350°F (-45 to 175°C) operating temperature

Description

The Chesterton 9K Anti-Extrusion Ring provides protection to pressurized dynamic and static seals (including O-Rings) from extruding into equipment clearances when under pressure. This protects seal components from premature failure and prolongs service life. Protection is provided by tight fitting anti=extrusion rings in the seal groove, thus minimizing the extrusion gap.

9K anti-extrusion rings are recommended for use when hydraulic system pressure or fluid pressure exceeds the seal's resistance limitation and normal system pressure or when the system temperature is high enough to lower the extrusion resistance of the seal. It can also be used when nonmetallic bearing bands increases the radial clearance and extrusion gap.

Need Help? Call a pump expert at 1-802-255-4003

We're open 8:30 am to 5:00 pm