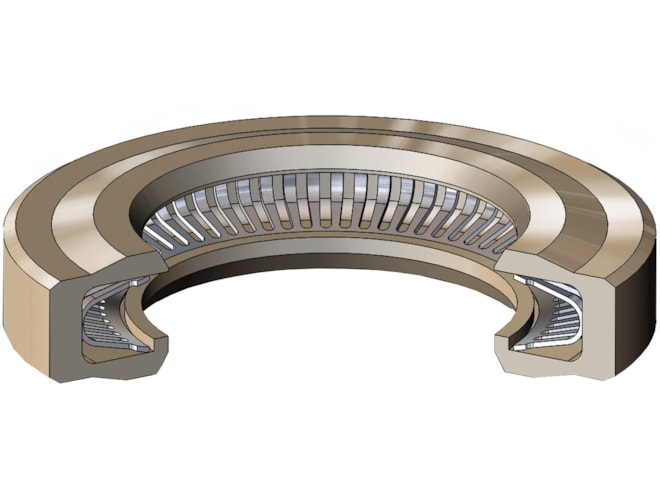

Chesterton 600 Spring Energized Seal

Continuous contact, spring energized seal for gas, cryogenic, and vacuum applications.

Overview

Features

- AWC300 (PTFE) Moly and Glass

- -250 to 400°F (156 to 204°C)

- AWC400 (PTFE) Carbon and Graphite

- -250 to 400°F (156 to 204°C)

- AWC510 (PTFE) Mineral Filled FDA

- -250 to 400°F (156 to 204°C)

- AWC520 (PTFE) Virgin Unfilled

- -250 to 400°F (156 to 204°C)

- AWC610 UHMWPE

- -425 to 180°F (-253 to 82°C)

- AWC630 PEEK

- -100 to 400°F (-73 to 204°C)

Description

The Chesterton 600 Spring Energized Seal is used when very high axial loading is required for challenging static and slow rotary oscillating applications. It is utilized in difficult static sealing applications such as gas, cryogenic temperatures, and vacuum. The spring design is useful in dynamic applications where high torque and clamping forces are present.

The continuous spring is U-shaped and manufactured with independent grooves originating in the center of the ring and progressing to the outside diameter. This design produces a continuous, heavy load at the sealing points. The continuous geometry of the spring, when wound in a circumference, minimizes expansion and contraction due to thermal effects. Each seal jacket is used in combination with a high performance, metallic, continuous spring to produce the required high contact load for the positive sealing force against the mating surface.

The materials used for the 600 Series consist of high performance fluoroplastic compounds and engineered plastics that provide a low coefficient of friction, high abrasion resistance, and dimensional stability. It has resistance to most fluids, chemicals, and gases

Need Help? Call a pump expert at 1-802-255-4003

We're open 8:30 am to 5:00 pm