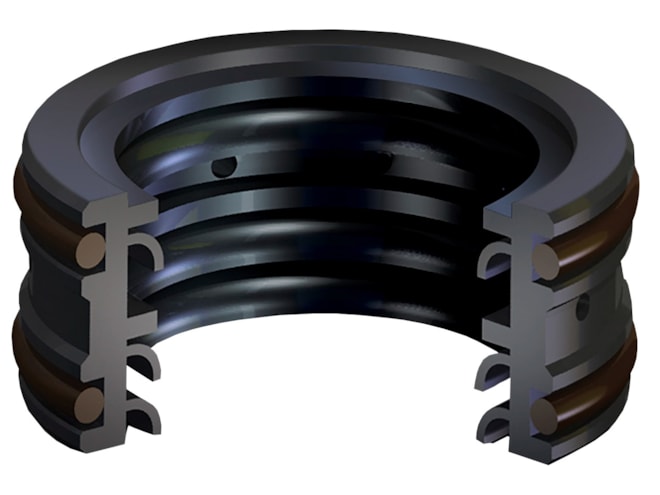

Chesterton 30KC Polymer Seal

Polymer cartridge for dynamic seal applications.

Overview

Features

- -20 to 300°F (-20 to 150°C) operating temperature

- 984fpm (5msec)

- 159psi (1mpa)

- Dynamic surface finish

- 8 to 16 μin (0.2 to 0.4μm)

- Static surface finish

- 16 to 32μin (0.4 to 0.8μm)

- AWC100 (PTFE) Polyimide

- 45 mating surface (Rockwell C)

- AWC300 (PTFE) Moly and Glass

- 55 mating surface (Rockwell C)

- AWC400 (PTFE) Carbon and Graphite

- 55 mating surface (Rockwell C)

- AWC510 (PTFE) Mineral (FDA listed)

- 45 mating surface (Rockwell C)

Description

The Chesterton 30KC Polymer Seal is used in dynamic rotary seal applications. The cartridge design uses high performance, filled PTFE material that is able to withstand the high shear rates, frictional heat, and abrasives that come when pumping high viscosity products or moving powders.

The 30KC consists of an inboard and outboard sealing element and built in flushing ports. The inboard lip seals process fluid, the outboard lips seal barrier fluid, and the flush port allows for flushing. The cartridge design is versatile and extremely tough, able to withstand adhesion between sealing surfaces and the shaft as a result of of reacted material and dry running capabilities. This results in the seal providing excellent fluid compatibility, temperature resistance and reduced frictional force in demanding applications.

Need Help? Call a pump expert at 1-802-255-4003

We're open 8:30 am to 5:00 pm