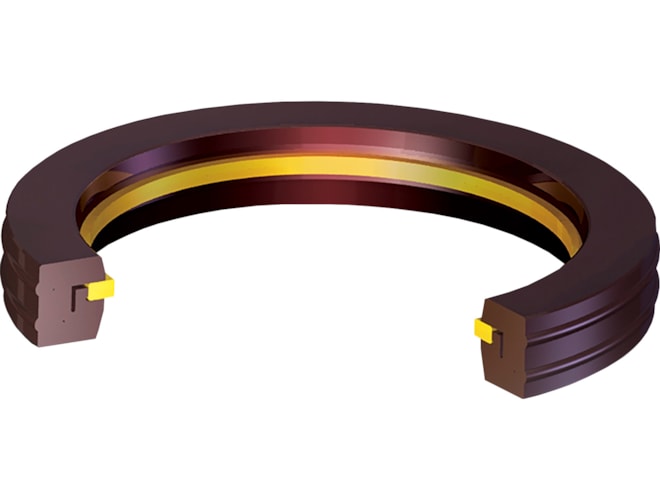

Chesterton 33K Lip Seal with Split Design

Unitized split seal for bearing and gearbox protection.

Overview

Features

- AWC800 Adapters (EU)

- 185°F (85°C) Temperature

- 2,500 fpm (12.70msec)

- 1psi (0.07 bar)

- AWC100 (PTFE) Polyimide

- ≥45 mating surface (Rockwell C)

- AWC300 (PTFE) Moly and Glass

- ≥55 mating surface (Rockwell C)

- AWC400 (PTFE) Carbon and Graphite

- ≥55 mating surface (Rockwell C)

- AWC860 Adapters (EU)

- 250°F (85°C) temperature

- 2,500 fpm (12.70msec)

- AWC100 (PTFE) Polyimide

- 10psi (0.7bar)

- ≥45 mating surface (Rockwell C)

- AWC300 (PTFE) Moly and Glass

- 1psi (0.07bar)

- ≥55 mating surface (Rockwell C)

- AWC400 (PTFE) Carbon and Graphite

- 1psi (0.07bar)

- ≥55 mating surface (Rockwell C)

Description

The Chesterton 33K Lip Seal with Split Design is a unitized split seal for bearing and gearbox protection. The split design minimizes the need for equipment disassembly. It lowers the risk of external contaminants penetrating the housing.

The seal is a combination of two different material types. The unitized housing is made from abrasion-resistant thermoset polyurethane that provides easy mounting to equipment. The seal can be installed in either direction which enables the sealer rings to be located away from a previously damaged shaft.

Documents

Manuals

- Chesterton 33K Lip Seal with Split Design Installation Instructions (English) (381 KB)

- Chesterton 33K Lip Seal with Split Design Installation Instructions (Spanish) (388 KB)

Spec Sheets

- Chesterton 33K Lip Seal with Split Design Datasheet (English) (695 KB)

- Chesterton 33K Lip Seal with Split Design Datasheet (Spanish) (698 KB)

MSDS

Need Help? Call a pump expert at 1-802-255-4003

We're open 8:30 am to 5:00 pm